Prop Scan Reports (Coming Soon)

By using a 3D scanner in conjunction with TrueProp Software we are able to provide a highly efficient and accurate method for propeller inspection and repair, moving beyond the limitations of traditional, manual tools. This combination offers several key benefits that improve performance, reduce costs, and streamline the repair process.

Why choose us to scan your props?

Enhanced Accuracy and Performance

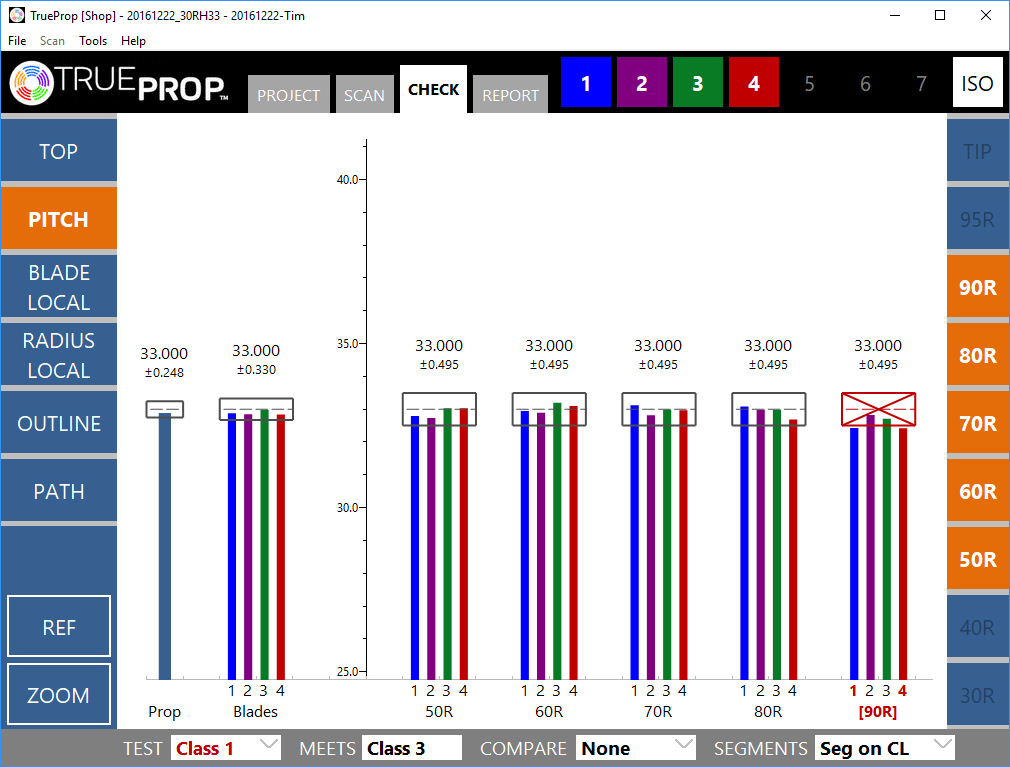

We use a 3D scanner that captures the entire geometry of a propeller, creating a dense point cloud of data with a high degree of precision. Specialized software then analyzes this data against design specifications and international standards, such as ISO-484. This process is far more accurate than using a manual pitchometer, as it can detect minute variations between blades that would otherwise be missed. By identifying and correcting these subtle inconsistencies, we can reduce blade-to-blade variation, which is a major cause of vibrations, propeller noise, and poor fuel efficiency. The result is a propeller that performs at its optimal level, often to a "better than new" condition.

Streamlined Workflow and Cost Savings

The portability of handheld 3D scanners allows our technicians to inspect a propeller without removing it from the vessel, whether it is on a lift or in a dry dock. This eliminates the need for heavy rigging and transportation, saving significant time, labor, and money. The ability to quickly determine if a propeller needs repair or is ready for service helps improve dry dock schedules and reduces vessel downtime.

Comprehensive Documentation and Reporting

Once the propeller is scanned and analyzed, we can provide detailed, professional reports. These reports provide a clear, objective record of the propeller's condition both before and after repair. They include visual aids and numerical data that document compliance with ISO standards, which gives customers confidence in the quality of the work and provides a valuable record for future maintenance.